References

Features

The study, the conception and the technical specifications are only suitable for tippers

– Max pressure : 200 bars

– Proof pressure : 300 bars

– Maximum speed : 0.2m/s

– Temperature : – 30°C to + 90°C

– Hydraulic mineral oil

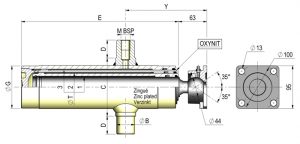

• Materials

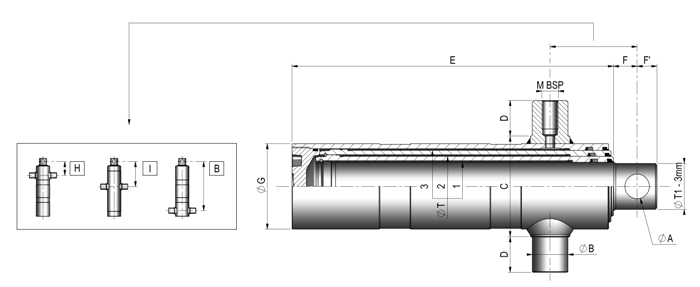

– Seamless tube NFA 49311/312 tube machined, ground, trated and polished Ra < 0.4µ

– Cold-drawn tube

– Round bar Steel C35R, machined, ground and polished Ra < 0.4µ

– Each component is nitrited (except cylinder

bottom)

• Seals

– Rod: compact polyurethane lip seal + 1 polyurethane

wiper seal

– Cylinder bottom: O RING 80 shore + back up

ring or static seal

• Marking

On the tube or bottom: REFERENCE + CH +

WEEK/YEAR of manufacture

• Testing by “pick up”

Recommendations

– Protect the hydraulic circuit by a relief valve and a filter;

– Check the state of purity of the fluid (foreign bodies);

– Remember to purge the cylinders and the

hydraulic circuit;

– Do not weld onto the cylinder;

– Do not, under any circumstances, use the

tipping system as a mechanical stop;

– Never allow the body to lean against the cylinder

when in stowed position (gap > 20mm).

• Storage:

– The cylinder rod must be greased before being

stored;

– Protect the cylinder shaft and trunnions during

high pressure steam cleaning.

• Spare parts: joint pockets, see price list.

• Instructions: on request.

• Guarantee: please refer to the general sales

conditions.

The normal operation of a CHAPEL telescopic

cylinder consists in the regular lifting of a tipper

body to progressively empty its load over its

path, whilst respecting the operating and safety

conditions.

A tipping system is solely a lifting device, it cannot,

under any circumstances, stabilise or guide

the tipper body.

On choosing a cylinder, the weight C is equal

to the weight of the body added to the weight of

the load.

Additional information

SAFETY PROCEDURES TIPPING

Plan a gap from 20 to 30mm

Ensure that:

– The necessary tipping pressure is less than

the maximum recommended operating pressure;

– The load is compatible with the vehicle;

– The ground is stable and flat;

– There are no people or obstacles in the working

perimeter (at ground level and high up),

– The load has been distributed uniformly;

– The tyre pressure is correct;

– The load is progressively emptied.

PAY ATTENTION to loads sticking in the body

(wet earth, etc…)

Strong adhesion to the body may cause the

vehicle to tip over.

THE FOLLOWING IS STRICTLY PROHIBITED:

– Do not move the vehicle during tipping;

– Rapid operation of the cylinder tipper control;

– Working under a raised tipper body that has

not been secured;

– Tipping if the wind is buffeting the vehicle.

«Not following the above safety procedures

may cause considerable over-pressures and

transverse forces that are not allowed by the

cylinder.

This may therefore cause considerable damage

and place the operator in danger.»