References

Features

– Max working pressure: 220 bars

(Warning : rod buckling, please see tables)

– Proof pressure: 330 bars

– Maximum speed: 0.5m/s

– Temperature: – 30°C to + 90°C

– Hydraulic mineral oil

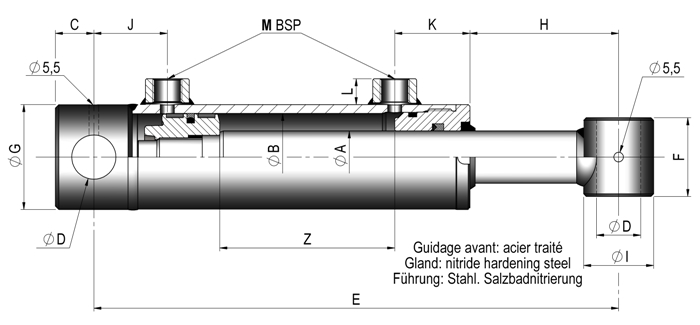

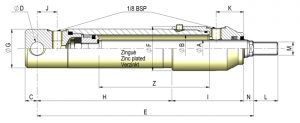

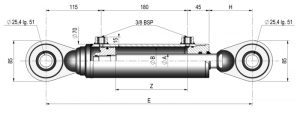

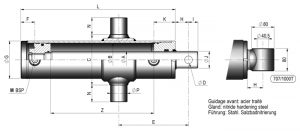

• Materials

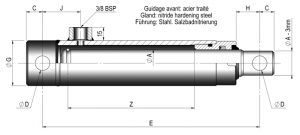

– Rod: CK45 chrome plated f7 Ra<0.2

– Chrome thickness 20μ mini

– Corrosion test: 209 hours NSS ISO9227

class9 (ISO4540) Hardness 900 HV

– Cold-drawn tube H9, Ra < 0,8 μ / skived and

roller burnished H9, Ra < 0,3 μ

– Gland: nitride hardening steel (38MF5)

– Piston: Steel C35R

• Seals

– Rod: compact polyurethane lip seal + 1 wiper

seal

– Piston: compact polyurethane seal + nitrile

(400 bar)

• Marking

– On the tube: REFERENCE + CH + WEEK/

YEAR of manufacture

• Testing: by “pick up”

• Protection

– Priming paint black RAL9005 except on type

707.5 and 707.10, wood splitter cylinder and

double acting cylinder crutch

– Zinc plating on micro cylinders

Recommendations

– Protection of the circuit by a relief valve and

a filter

– Check the oil cleanness (pollution)

– To bleed the air from the cylinder and the

hydraulic circuit

The cylinder should not, under any circumstances, be used as a mechanical limit stop for

moving loads.

For double-acting cylinders working as singleacting, it is essential to connect the unused port

to the tank or safe environment

• Welding: do not weld on the tube. Dismount

the cylinder to weld on the rod or on the base

• Storing: storage of extended cylinder, the rod

must be greased. For high pressure cleaning,

protect the rod.

• Dismantling the cylinder : Warning : we use

loctite engineering adhesive and a special locking ring to fasten the piston to the rod. Once

the piston has been removed it will require

a new locking ring and re-application of the

appropriate loctite.

Additional information

Spare parts

• Seal kits see price list

• Technical notice on request

• Warranty: see our standard terms of sale