References

| Reference | ØA | ØB |

Z Course Stroke Hub |

H | I | B | ØT1 | ØT2 | ØT3 | ØT4 | ØT5 | ØT6 | ØT7 |

Nombre de sections Number of sections Anzahl elemente |

A |

A Poussée Thrust Schub |

B | C | D | D max | E | F | F' | F min | G | H | HT min | I | J | K | L | M | N | O | P | T | X | X min | Y | Max* | Vol. (Ltr) | Vol. (cm3) |

Pression Pressure Druck (bar) |

Vérin Cylinder Zylinder |

Débit Flow Leistung (vol) |

Débit Flow Leistung (Ltr min) |

Poids Weight Gewicht (Kg) |

Pression max Max pressure Max druck |

Débit max Max flow Max leistung |

Rapport de pilotage Pilot ratio Aufsteuerung |

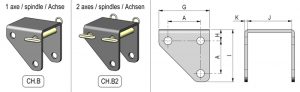

OPTION Berceau Cradle Ring N° |

Capacité réelle de levage du vérin à 200 bars (Tonnes) |

Longueur Length Länge (m) |

pressostat |

Téléchargement Download |

||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

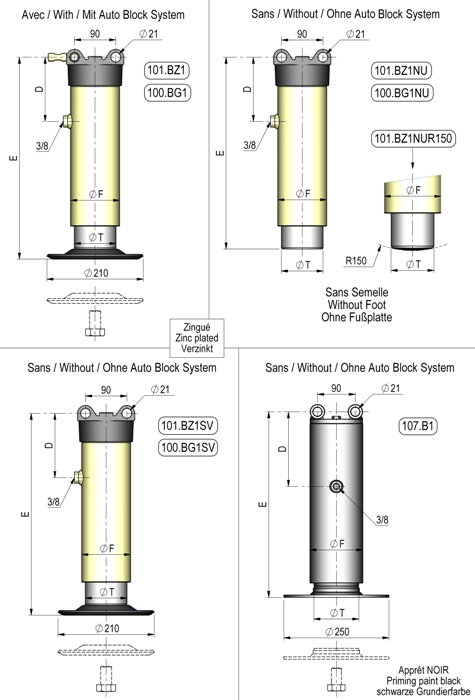

| 101.BZ1 | 190 | 135 | 390 | 90 | Ø68 | 1.5 | 14.2 | ||||||||||||||||||||||||||||||||||||||||||||||||||

| 101.BZ1NU | 190 | 135 | 368 | 90 | Ø68 | 1.5 | 12 | ||||||||||||||||||||||||||||||||||||||||||||||||||

| 101.BZ1SV | 190 | 135 | 390 | 90 | Ø68 | 1.5 | 14 | ||||||||||||||||||||||||||||||||||||||||||||||||||

| 101.BZ1NUR150 | 190 | 135 | 368 | 90 | Ø68 | 1.5 | 12 | ||||||||||||||||||||||||||||||||||||||||||||||||||

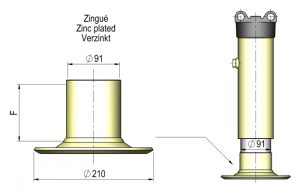

| 100.BG1 | 230 | 140 | 440 | 109 | Ø91 | 3.4 | 17 | ||||||||||||||||||||||||||||||||||||||||||||||||||

| 100.BG1NU | 230 | 140 | 418 | 109 | Ø91 | 3.4 | 14.8 | ||||||||||||||||||||||||||||||||||||||||||||||||||

| 100.BG1SV | 230 | 140 | 440 | 109 | Ø91 | 3.4 | 16.7 | ||||||||||||||||||||||||||||||||||||||||||||||||||

| 107.B1 | 250 | 178 | 438 | 126 | Ø107 | 4.3 | 25 |

Features

– Single acting cylinder with spring return /

main application is for hitch / stabilizer legs.

– Maximum pressure: 200 bars

– Maximum speed: 0,2 m/s

– Temperature: -30°c to +90°c

– Hydraulic mineral oil

• Materials

– Cold drawn Tube

– Cylinder bottom: cast iron ggg

• Seals

– Rod: compact polyurethane lip seal

– polyurethane wiper

• Marking

On bottom or cylinder tube: reference + ch +

week/year of manufacture

• Testing: by pick up

• Protection

– Outside tube: zinc plated

– Cylinder foot: cataphoresis

– Spindles: zinc plated

Recommendations

– Check the oil cleanness

– Use a handpump to feed the cylinder crutch

– To ensure good operation of the autoblock

system, grease regularly

• Welding

Do not weld on the tube, rod and bottom

• Storing

For a long storage in bad weather, the rod

must be retracted and greased

• Spare parts

– Seal kit, see price list.

– Cyilinder head

• Technical notice on request

• Warranty: see our standard terms of sale

Additional information

• Hydraulic crutch fully protected against

corrosion.

• Finished product ready to mount.