News

Innovation – Increased stroke for telescopic cylinders – heavy-duty series

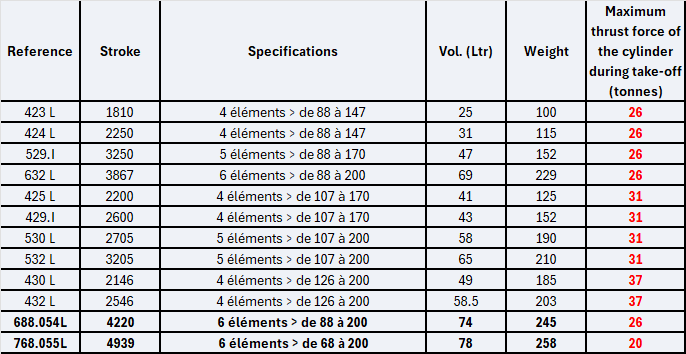

CHAPEL is expanding its range of single-acting telescopic cylinders with two new strokes:

➡ 4,220 mm: 6 elements with diameters ranging from 88 to 200 mm

➡ 4,940 mm: 7 elements with diameters ranging from 68 to 200 mm

Thanks to these long strokes, the cylinder can be mounted further forward on the chassis, which allows for:

✅ Less reinforcement of the chassis and body

✅ Less stress and lower total unladen weight

If you would like further information about these references, please do not hesitate to contact our sales department.

CHAPEL — French specialist in the manufacture of telescopic cylinders for tipper since 1979.

FR : ventes@chapel-hydraulique.com

DE : sales@chapel.de

🔍 Technical Focus — Position Sensors for Hydraulic Cylinders

At CHAPEL, we offer several position sensing solutions for your hydraulic cylinders, each tailored to your specific application needs.

Here’s an overview of our three sensor technologies 👇

⚙ Cable Sensor

Versatility and simplicity:

- Adapts to a wide range of stroke lengths

- Requires a simple rod machining

- Less suitable for fast or abrupt movements (due to mechanical inertia and cable tension)

Operating principle:

As the cable extends, it drives a rotary encoder that converts the rotation into an electrical signal.

💡 An ideal solution for standard applications with variable stroke requirements.

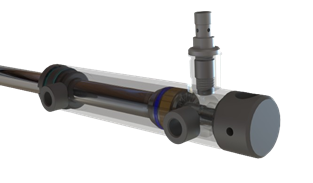

🧲 2. Magnetostrictive Sensor

Precision and durability:

- Custom-designed sensors adapted to the cylinder stroke

- Requires a hollow rod

- High accuracy and repeatability

- No wear — no mechanical contact

- Excellent resistance to shocks and fast movements

Operating principle:

A current pulse is sent through the waveguide.

When it reaches the movable magnet (attached to the rod), it generates a torsional wave that travels back to the sensor head.

By measuring the travel time of this wave, the system precisely determines the position of the magnet, and thus of the cylinder.

💡 Perfect for demanding applications requiring precise, durable, and maintenance-free position measurement.

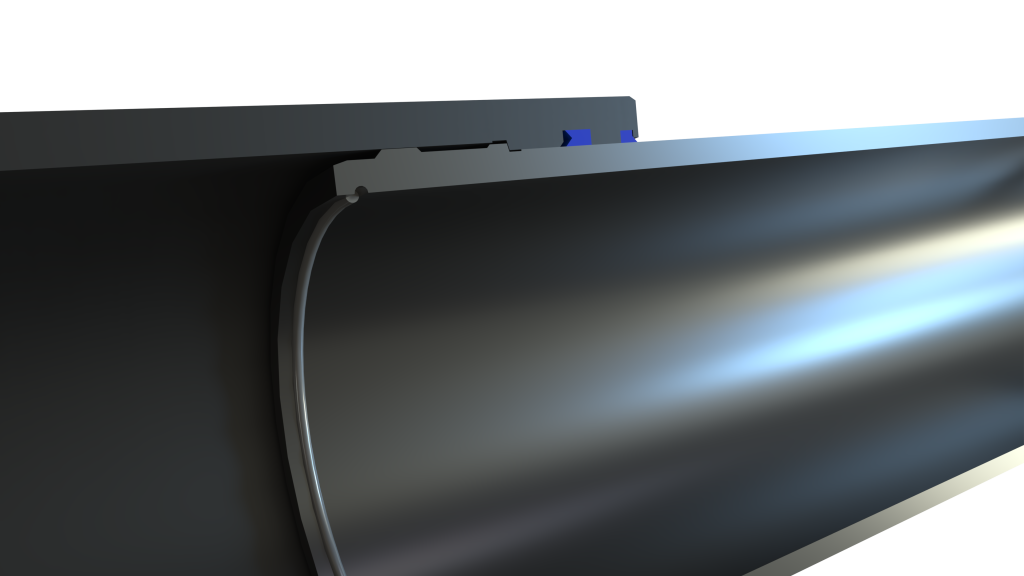

🧩 3. End-of-Stroke Sensor

Simplicity and reliability:

- Provides information only at fully retracted and/or fully extended positions

- Cost-effective solution

- On/off signal

- Available in different technologies: contact, inductive, etc.

💡 A reliable and economical option for applications that only require end-position detection.

🏁 In short

Whether you’re looking for simplicity, precision, or robustness, CHAPEL supports you in selecting the best sensor solution for your hydraulic cylinders.

👉 Contact our technical team to learn more or to design a custom-made configuration for your project.

FR : ventes@chapel-hydraulique.com

DE : sales@chapel.de

CHAPEL at AGRITECHNICA 2025! 🌾

We’re excited to announce that CHAPEL will be participating in the Agritechnica trade fair, held in Hanover, Germany, from November 9 to 15, 2025.

Come and visit us at Hall 16 – Stand D48 to share your projects and discover our latest product.

We look forward to seeing you there and sharing this great event together!

See you soon at Agritechnica 👋

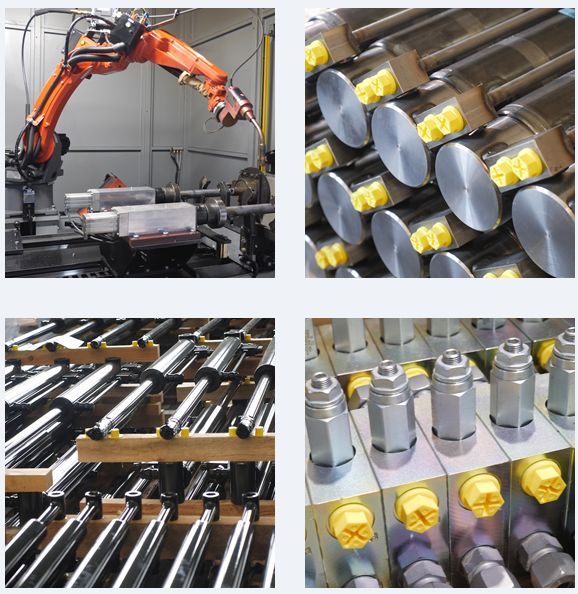

Custom-made cylinders, big diameters, long strokes

Custom-made cylinders, big diameters, long strokes!

Always attentive to the needs of our customers, we are expanding our offer with the production of big diameter and long stroke hydraulic cylinders, designed to meet the highest demands in complex environments.

New dimensions available*:

- Rod diameter: up to 100 mm

- Piston diameter: up to 240 mm

- Stroke length: up to 3,300 mm

- Finishing paint available according to your requirements

*Please ask your usual contact to check our possibilities

Applications:

- Civil engineering / Construction

- Agriculture

- Energy (offshore wind power, hydraulic)

- Maritime & offshore

- Special machines / Presses

Why choose us?:

- In-house engineering department for comprehensive technical support

- Custom-made manufacturing, from small to large series

- Rigorous quality control at every stage

- ISO 9001 certification, ensuring reliability and quality

- 50 years of expertise in the field of hydraulic cylinders

Feel free to contact us if you need further information !

The CHAPEL range of telescopic cylinders: a quality offering like no other

Dear customers and partners,

At Chapel, we have always taken pride in offering cylinders that combine strength, sustainability and compliance with environmental standards. With our range of telescopic cylinders, we are setting the competitive standard.

And here’s why.

Robust and long-lasting

Our cylinders are designed with parts machined from solid, ensuring optimum mechanical strength. This design ensures a working life in exceeding 20 years, far beyond market standards.

As proof of this, some of our customers are replacing the seals on cylinders that are over 30 years old!

Our treatment: a sustainable, high-performance solution

We have opted for nitrocarburizing and post-oxidation to ensure maximum protection and performance:

- Nitrocarburizing (standard on all our telescopic parts): excellent resistance to wear and friction, as well as classic corrosion resistance.

- Post-oxidation: optional extra layer offering superior corrosion protection (x3 compared with conventional resistance).

Our treatment modifies the physical structure of the steel itself, making it much more resistant to impact and extending the lifetime of the corrosion protection, unlike coating processes such as chrome plating, zinc plating and painting.

A more eco-friendly choice.

Post-oxidation and nitrocarburizing offer major ecological advantages:

- Toxicology, ecotoxicology: nitrided elements do not contain hexavalent chromium (Cr6), which is becoming increasingly regulated.

- Eco-friendly process: our treatment processes (gas or salt bath) generate few or no waste products, and waste can be fully recycled to produce new reagents with virtually no impact on the environment.

- In comparison with chrome: traditional chromium plating offers variable resistance (96h/120h in class 9 BS for the most common applications, and between 24h and 1000h depending on production methods). Post-oxidation is therefore a high-performance, eco-friendly alternative.

French production and European sourcing

- Our cylinders are manufactured in France using rigorous European sourcing, guaranteeing an optimised carbon footprint.

- We offer a wide range of fittings (rod ends, spherical plain bearings, trunnions) and supply fittings to suit all your needs.

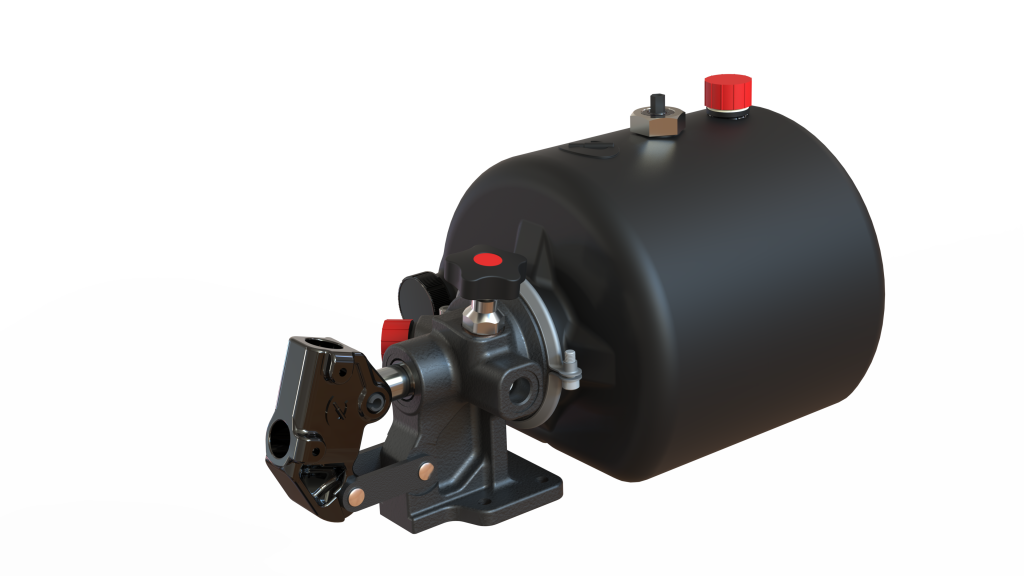

FLEXePUMP CHAPEL: The Simple and Efficient Solution for Your Tipping Operations

The CHAPELFLEXePUMPhas been specifically designed to meet the needs of demanding professionals. It’s your reliable partner for daily operations, combining robustness, simplicity, and reliability.

Easy to Use All you need is a power drill to operate it. No more complex systems or wasted effort: just turn it on and you’re done.

👉 See the FLEXePUMP CHAPEL in action here:

👉 https://youtu.be/oEHg3ZyaVvM

Horizontal Mounting for Maximum Flexibility

The FLEXePUMP can be adapted to all working configurations thanks to its horizontal mounting.

Whether you face space constraints or have specific requirements, its quick and simple installation optimizes your work environment and ensures enhanced performance.

Always Ready, Even in Unexpected Situations

Power drill failure? No drill available?

No problem. The FLEXePUMP remains fully operational thanks to its integrated hand pump. You can continue your operations without any interruptions, ensuring maximum productivity.

➜ For More Than Just Tipping: FLEXePUMP Double-Acting VersionFor applications beyond tipping, the FLEXePUMP is also available

New for 2025: The Double acting FLEXePUMP

CHAPEL continues to innovate with the Double acting FLEXePUMP.

This new version brings significant improvements:

Easy to use > for faster and more efficient operations

Enhanced versatility to meet a wide range of needs

Optimal efficiency with its double-acting system

The Double-Acting FLEXePUMP is designed to meet the highest demands.

Chapel Hydraulique will be exhibiting at a trade fair in Germany!

We are pleased to inform you that Chapel Hydraulique will be exhibiting at a trade fair in Germany dedicated to professionals in our business sector.

This exhibition will be an opportunity for us to present our hydraulic cylinder solutions and to discuss with you about any projects you may have. Whether you’re looking for new products or technical advice, our team will be on hand to meet your needs.

DEFINITIVE END OF MANUFACTURING OF STEEL TANKS.

Dear customers,

In recent years, we have observed a decrease in demand for steel tanks, with a growing preference for plastic models. Due to this shift, we are no longer able to maintain sufficient production volumes to ensure competitive pricing on steel. As a result, we have decided to focus our production exclusively on plastic tanks.

To facilitate this transition, we have developed an adapter bracket that allows the same fastening systems to be retained, ensuring compatibility with your existing installations.

The installation of this bracket maintains the same mounting holes (except for 1L tanks), but you will still need to check the overall dimensions. You can contact our sales department, which will provide the plans for verification.

Thank you for your understanding, and feel free to reach out to us with any questions or requests.

We thank you for your confidence and remain at your disposal for any questions

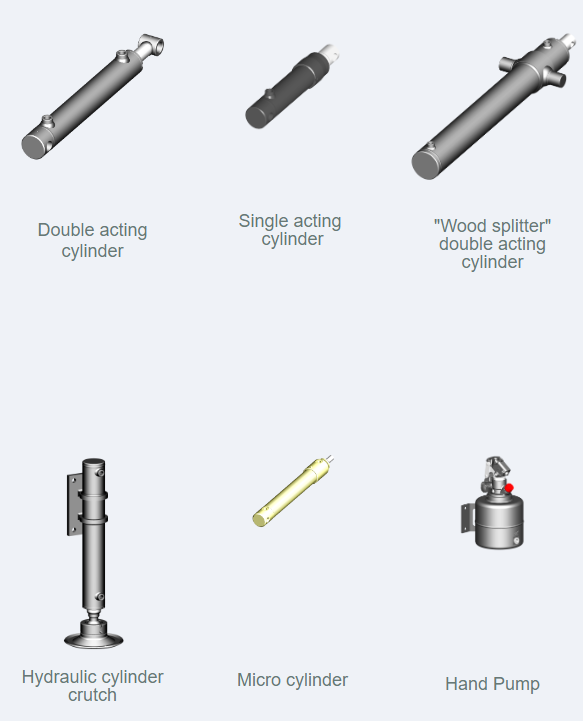

STANDARD CYLINDERS AVAILABLE ON STOCK

All our standard products are available on stock :

- Black primer on the cylinders except for cylinder crutch and “wood splitter”

- Zinc-plated double-acting micro cylinders

- Wood Splitter

- Crutch

- Telesocpic cylinders

Option :

- Finish painting available within 2 weeks (colour upon request)

- Adaptable double pilot operated check valve and over center valves

Our entire range of products is manufactured in France

For your enquiries, please contact us !

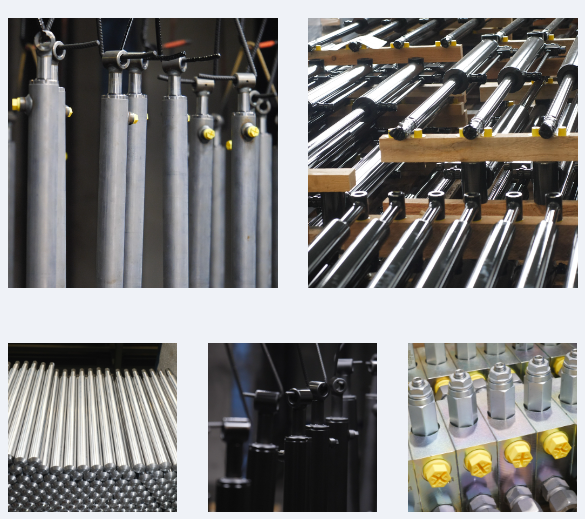

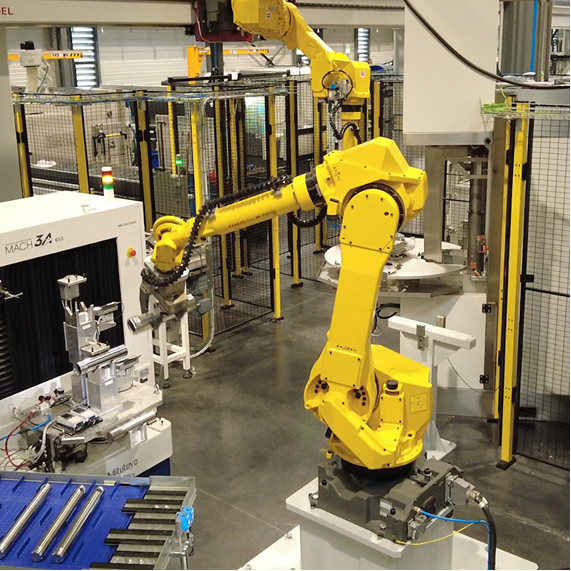

INCREASING PRODUCTION CAPACITIES

CHAPEL Group

6 production units in France, 2 in Germany

Increasing production capacities that allows us

to have 8 weeks lead time

Fully automatized production lines

PRODUCTION OF TELESCOPIC CYLINDERS

The leading European manufacturer of hydraulic cylinders and hand pumps.

Increasing our production capacities for telescopic cylinders

- 2 production plants in France : our last production unit, which was launched last year, is fully robotized

- A manufacturing capacity of over 90,000 telescopic cylinders per year

- A wide range of cylinders for light tipping vehicles <3.5T with zinc plated outside tube for a longer durability

- A wide range of telescopic cylinders for heavy tippers for agricultural trailers and public works

- Oxynitrocarburized components to provide high levels of corrosion and impact protection

- Customers across 5 continents.

FLEXePUMP

AND AN EMERGENCY HAND PUMP

The best of both worlds: Manual & Gear Pump to manage every situation!

use your electric screw driver for a maximum efficiency.

No more battery? No problem, your hand pump will do the job!

If you need further information, please feel free to contact our sales department.

By phone : +33 (0) 476 07 20 46

By mail : ventes@chapel-hydraulique.com